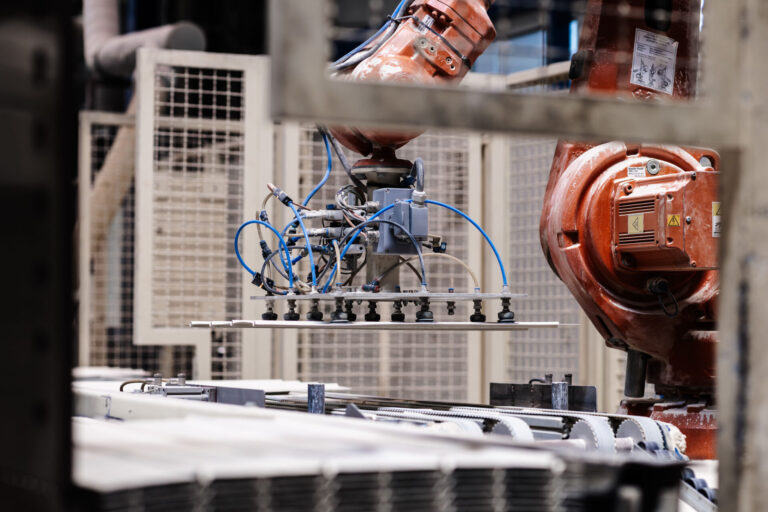

Ceram Austria GmbH has been producing SCR catalysts since 1985. CERAM catalyst is manufactured at our sole production facility in Frauental, Austria. This manufacturing consistency, the quality of our raw materials and products, and the ingenuity of our production team set us apart from our competition.

Our catalysts are an integral component in the SCR process (Selective Catalytic Reduction). This process is used in fossil fuel power plants, waste incineration plants, stationary diesel engines, industrial plants, heavy commercial vehicles, and any application where nitrogen oxides (NOx) reduction is required. In the SCR process, the nitrogen oxide compounds contained in flue gases are converted into nitrogen and water vapor, both natural constituent elements of air. SCR technology is a significant contributor to reducing ground-level ozone, acid rain and the greenhouse effect.

CERAM catalysts are used successfully in a wide variety of applications worldwide. Our clients benefit from our diverse experience in applications involving nearly every conceivable fuel type and quality.

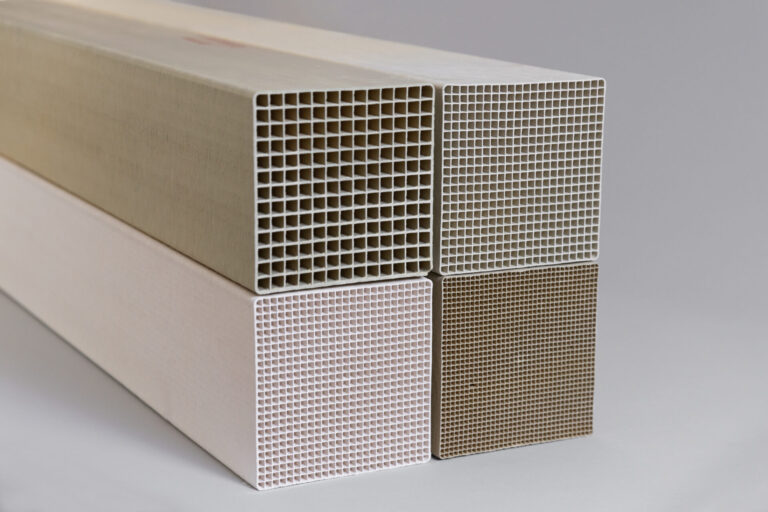

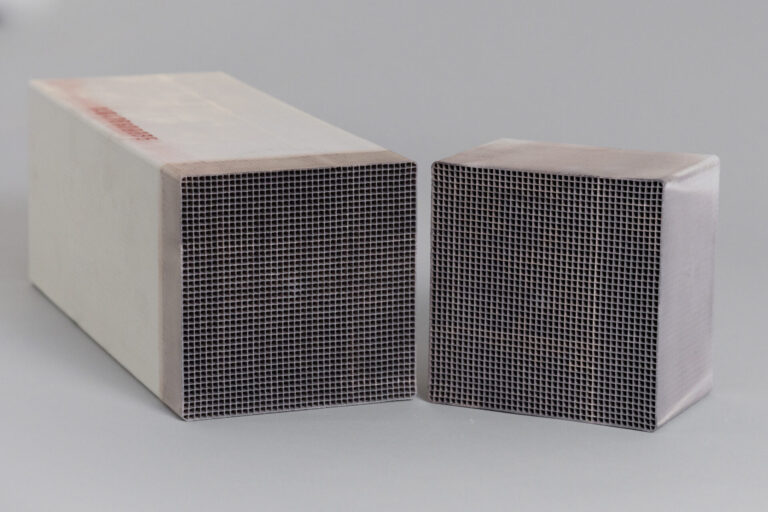

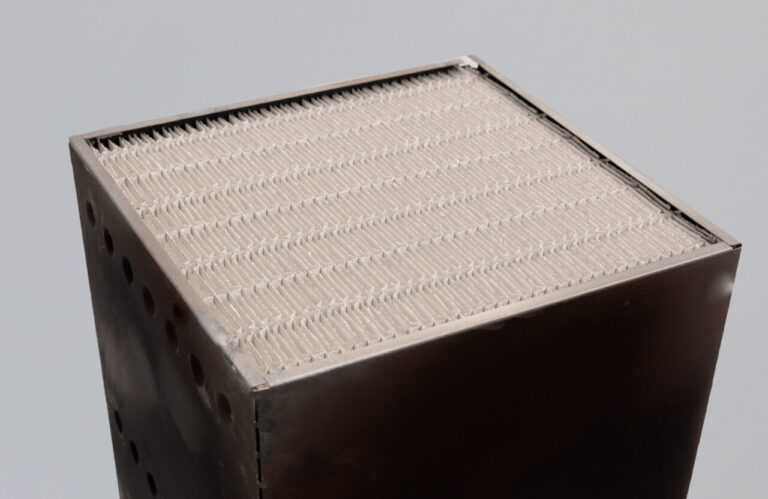

CERAM honeycomb catalysts are tailored to the exact specifications of each application. Our honeycomb products are designed for a wide variety of temperatures, particulate loadings, and fuels.

For specific inquiries about our products and applications please see below or directly contact Ceram USA.

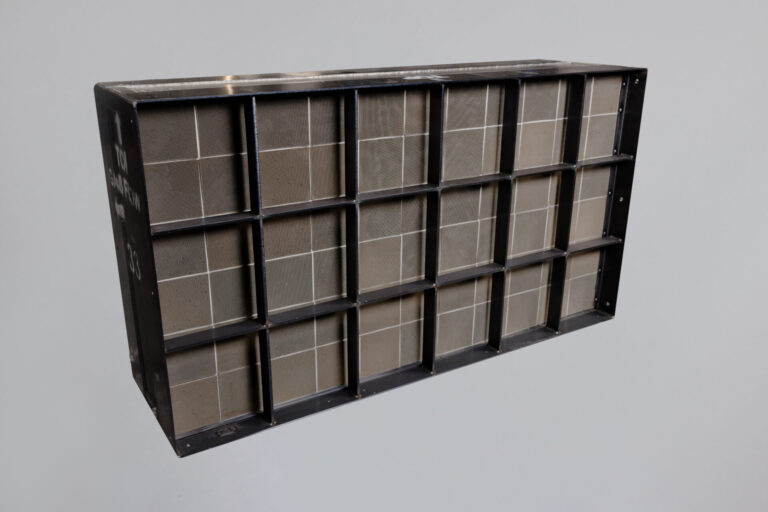

CERAM produces plate catalysts primarily for use in the energy industry. The catalyst material, which mainly consists of titanium dioxide, tungsten and vanadium, is applied to a stainless-steel substrate and subsequently calcined. Plate-type catalysts are particularly suitable for applications with very high ash fuels or for other applications in which the fly ash is prone to fouling other catalyst geometries such as Powder River Basin (PRB) or subbituminous coal applications.

For specific inquiries about our products and applications please directly contact Ceram USA.

CERAM oxidation catalysts reduce carbon monoxide, volatile organic compounds (VOCs) and ammonia emissions. CERAM utilizes a ceramic titanium dioxide catalyst substrate with precious metals as the catalytically active components.

CERAM has adapted our catalyst technology to a combination catalyst capable of both NOx reduction and CO, VOC and NH3 oxidation at the same time. Contact the Ceram USA team for additional information.

Our catalysts are also used for the decomposition of dioxins and furans. Catalytic dioxin decomposition is the only process that does not produce any substances requiring disposal.

For specific inquiries about our products and applications please contact Ceram USA